08.09.2017, RADFORD, VA– Thomson Industries, Inc., a leading manufacturer of mechanical motion control solutions, has announced availability of new synchronization capabilities for its Electrak® HD heavy duty electromechanical linear actuators. Designers of equipment in which large or awkward loads must be moved repeatedly and evenly, such as large solar panels or heavy hoods on construction equipment, can now simultaneously distribute that load using up to four actuators.

The Thomson Electrak HD, which boasts the most advanced onboard controls of any actuator in its class, has added a synchronization option to its feature set.

Traditional methods for synchronizing multiple actuators can be inflexible. Gas spring technology, for example, is limited in application, while hydraulic cylinders can be prone to leakage and costly to maintain. Non-integrated electronic systems have more flexibility and are cleaner but require external devices such as encoders and potentiometers to track position and send feedback to an external PLC or other logic solver.

“The ability to synchronize movement of large and potentially awkward loads is something our customers have been requesting as they seek to automate larger applications or improve ergonomics,” said Chad Carlberg, Product Line Manager for Industrial Actuators at Thomson. “We are pleased to announce that we have tapped into the advanced electronics capabilities of our popular Electrak HD heavy duty linear actuator technology to achieve synchronization more easily and cost effectively than is possible with any other available approach.”

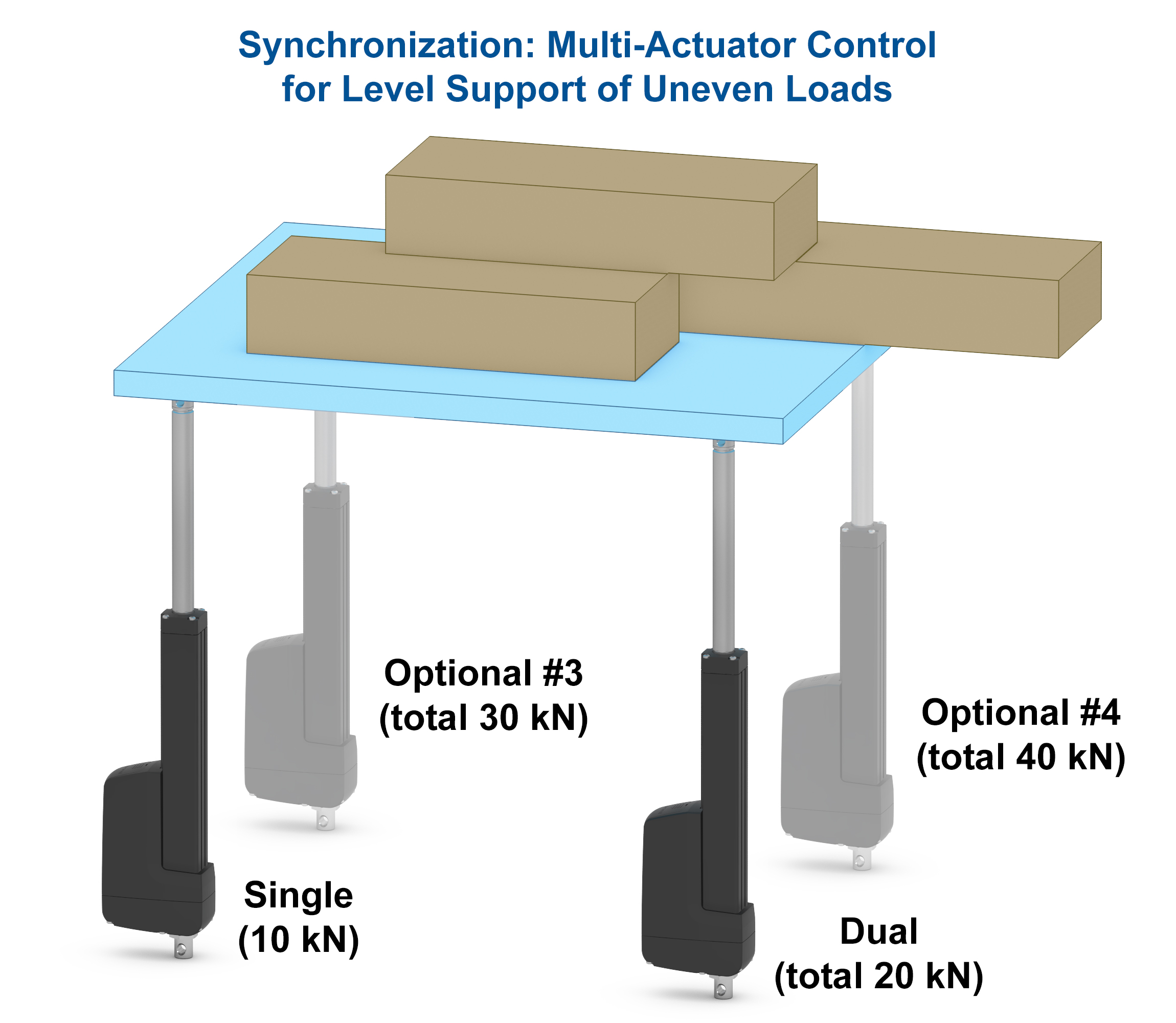

Synchronization enables motion integration of up to four Electrak HD actuators. When multiple units with the synchronization option are installed, designers can take advantage of a more stable and potentially quicker lift, no additional guides, and improved handling of uneven loads.

Thomson achieves its synchronization by embedding all load handling technology into a single electromechanical actuator, which is then wired in sequence with up to three other similarly equipped actuators. Designers install these wherever linear movement is needed without the need for external assemblies. Once the actuators are installed, customers synchronize them instantly by wiring them together and operating a single unit with a simple switch. During operation, system electronics detect speed changes that indicate load imbalances, thereby eliminating bouncing or other effects of imbalance.

By using multiple actuators, synchronization increases system movement speed more efficiently. A larger load that might normally use a single, heavy load actuator, for example, could be moved faster by combining multiple, lower load actuators. Synchronization also retains all Electrak HD mechanical capabilities, including the handling of bidirectional loads of up to 10 kN (2250 lbf) with stroke lengths up to 1000 mm (39 in) and accuracy of 1% of stroke from 100-1000 mm. High-quality ball screw assemblies provide efficient current draw and support speed options up to 43.5 mm/sec (1.7 in/sec) (using the 1.7 kN [382 lbf] version).

Applications

There are numerous opportunities to apply the benefits of synchronization. In addition to solar panels and off-highway agricultural equipment mentioned earlier, potential applications include:

- Industrial logistics trains for automatic correction of imbalances between the front and backend loads, which can cause stoppage, noise or unnecessary wear.

- Doors on ovens and large processing equipment for smoother, safer opening and closing.

- Ergonomic patient-handling equipment such as lift tables, synchronizing operation of lift columns for smoother movement and higher-quality patient experience.

- Marine applications, such as rudder assemblies, for smoother, more responsive steering.

- Structural engineering applications such as automatic loading doors in factories and warehouses.

Availability

Electrak HD linear actuators with synchronization capability are available immediately (choose SYN in “Electronic Options” after selecting an actuator part number). The same actuator can function as a master or slave in any multiple-unit configuration, simplifying replacement and reducing spares requirements.

http://www.thomsonlinear.com/website/com/eng/products/actuators/electrak_hd_products.php

About Thomson Industries, Inc.

With more than 70 years of motion control innovation and quality, Thomson is the industry’s premier producer of Linear Ball Bushing® Bearings and Profile Rail Bearings, 60 Case® Shafting, Ground and Rolled Ball Screws, Linear Actuators, Gearheads, Clutches, Brakes, Linear Systems and related accessories. Thomson invented the Linear Ball Bushing Bearing in 1945 and has set the standard ever since with an unsurpassed set of mechanical motion control solutions serving global commercial and aerospace and defense markets. Thomson has facilities in North America, Europe and Asia with more than 2000 distributor locations around the world.

Thomson Industries, Inc., 203A West Rock Road, Radford, VA 24141; 1-540-633-3549; 1-540-633- 0294 (fax); Thomson@thomsonlinear.com; www.thomsonlinear.com.